DBS deliver ADI Segmented Girth Gear

The team at the David Brown Santasalo (DBS) purpose-built state-of-the-art facility in Jyvaskyla, Finland were delighted to have a further opportunity to work with Europe’s largest iron ore producer, manufacturing another impressive segmented ADI (Austempered Ductile Iron) girth gear.

This particular customer was one of the DBS Finnish team’s first customers for the then-new helical segmented ADI girth gear concept for horizontal mills more than a decade ago, the gear has been running without issue ever since. The customer, pleased with the longevity and quality of the gear, returned to DBS for several similar gears with this being the latest.

DBS aimed to push gear technology development forward with these ADI-segmented gears, and the results have been very promising. The customer approached the DBS team because they required a replacement for an existing traditional-type gear that was in operation at their facility.

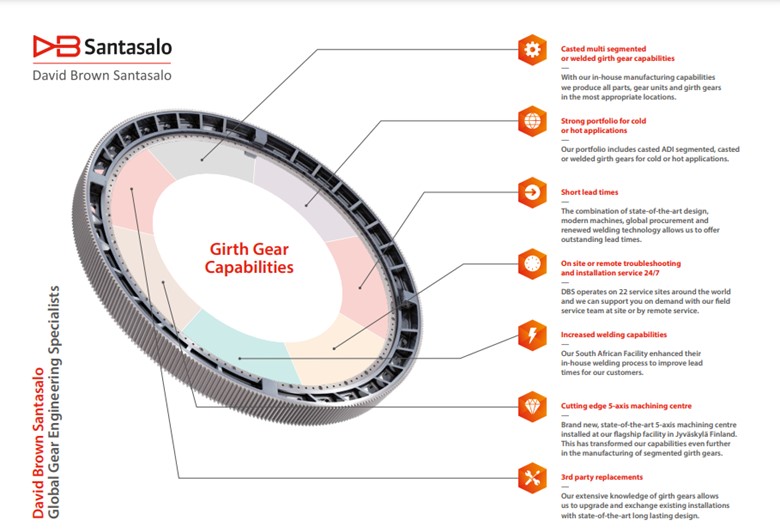

This particular gear is running a Ball Mill as a part of the customer's iron ore grinding circuit, DBS delivered the 7-meter diameter ADI segmented girth gear, weighing 16.4 tons and comprising of 12 segments. All produced in-house by DBS, which means they can offer competitive lead times. DBS can deliver:

- Girth gears of between 10 and 20 segments, and up to 1,800mm in length, which when bolted together make an immensely strong and precise diameter gear

- Significant reduction in lead-times

- Easy transportation, warehousing and storage

- Can be fitted to a single container

- Fast and easy installation and replacement

- Perfect to replace an existing 2-4pc fabricated girth gear

Get in touch with the DBS team at capital@dbsantasalo.com to find out how they can help you with your operations.