Update on the National Center for Gear Metrology

Bruce L. Cox

(This work of authorship and those incorporated herein were prepared by contractor as accounts of work sponsored by an agency of the United States Government. Neither the United States Government or any agency thereof, nor contractor, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, use made, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise, does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency or contractor thereof. The views and opinions of authors expressed herein do not necessarily state or reflect those of the United States Government or any agency or contractor thereof.)

Introduction

The National Center for Gear Metrology (NCGM) was established in October 1994 as a result of $3-million stipend awarded through the Department of Defense’s Technology Reinvestment Program. A partnership was formed between the American Gear Manufacturers Association, the American Society of Mechanical Engineers, National Institute of Standards and Technology, Pennsylvania State University and Department of Energy National Nuclear Security Agency (NNSA) Y-12 National Security Complex to establish the NCGM. The center, located in Oak Ridge, Tennessee, contains state-of-the-art coordinate measuring machines (CMM) for the calibration of all types of gear artifacts.

Kevin Martin measuring a length artifact on a Moore M48 CMM.

Capabilities

The NCGM is climate controlled to a temperature of ± 0.1° C. It has two Leitz 866 PMM CMMs, a Federal Formscan 3200 circular geometry instrument and a Moore M32 CMM. Also located in a nearby laboratory is a Leitz 866 PMM CMM with an optical head, a Moore M48 CMM, two super micrometers and a Talyrond roundness instrument. Types of gear artifact calibrations performed include involute profile, helix, index, pin and master gears. Involute profile and index of fine pitch master gears can be calibrated on the Leitz 866 PMM CMM with the optical head. The types of gear artifacts that have been calibrated include Fellows, ITW, Höfl er, Klingelnberg, Koepfer and Maag. Special types of artifacts can be calibrated upon request.

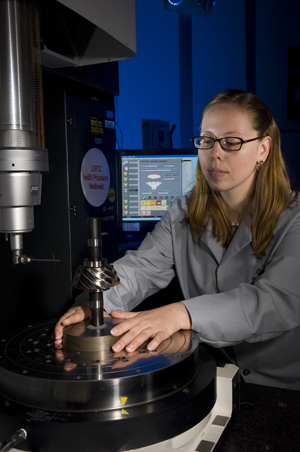

Suzanne Canning measuring a bevel gear artifact on a Leitz PMM.

Uncertainty

The NCGM is the only laboratory accredited for gear artifact calibration by the National Voluntary Laboratory Accreditation Program (NVLAP). The uncertainties for gear artifact calibration were co-developed by the NIST. Traceability to national or international standards is provided under the guidelines of ANSI/ISO/IEC 17025-2005. Stated uncertainties are as follows:

- Involute profile 0.9 micrometers

- Helix 0.8 to 1.4 micrometers

- Pin offset 0.7 micrometers

- Pin diameter 0.5 micrometers

- Pin roundness 0.3 micrometers

- Index and runout 1.6 arcseconds

Future Plans

The controllers for the Moore M32 and M48 CMMs are being upgraded. The new controllers will provide expanded capability and hopefully lower uncertainties to be developed. Plans also include expansion into bevel gear calibration. Intercomparisons with other international metrology institutes will continue to be conducted to ensure that the calibration uncertainties are equivalent with other laboratories worldwide.

For more information:

Bruce L. Cox

Babcock & Wilcox Technical Services Y-12, LLC

P. O. Box 2009

Oak Ridge, TN 37831-8091

Phone: (865) 574-1524

Fax: (865) 574-2802

www.y12.doe.gov/capabilities/metrology/